Vessel Ship Repair and Modernization

ECR holds numerous Indefinite Delivery Indefinite Quantity Contracts for various Navy vessel assets in the Virginia location. We hold both a non-complex, as well as a complex Multiple Award Contract-Multi Order (MAC-MO) contract with MARMC, the Navy’s Mid-Atlantic Regional Maintenance Center. We also hold an IDIQ contract for HM&E work for Military Sealift Command vessels. ECR has been the prime contractor on numerous PC Class DPMAs and Berthing Barge modernizations conducted in its Portsmouth, VA location as well as numerous non-complex and complex Continuous Maintenance Availabilities (CMAVs) on all classes of surface ships conducted at the Naval Station in Norfolk VA and JEB Little Creek. ECR has also been a strategic partner as a subcontractor for larger Navy Ship Repair Availabilities on SRAs and DSRAs.

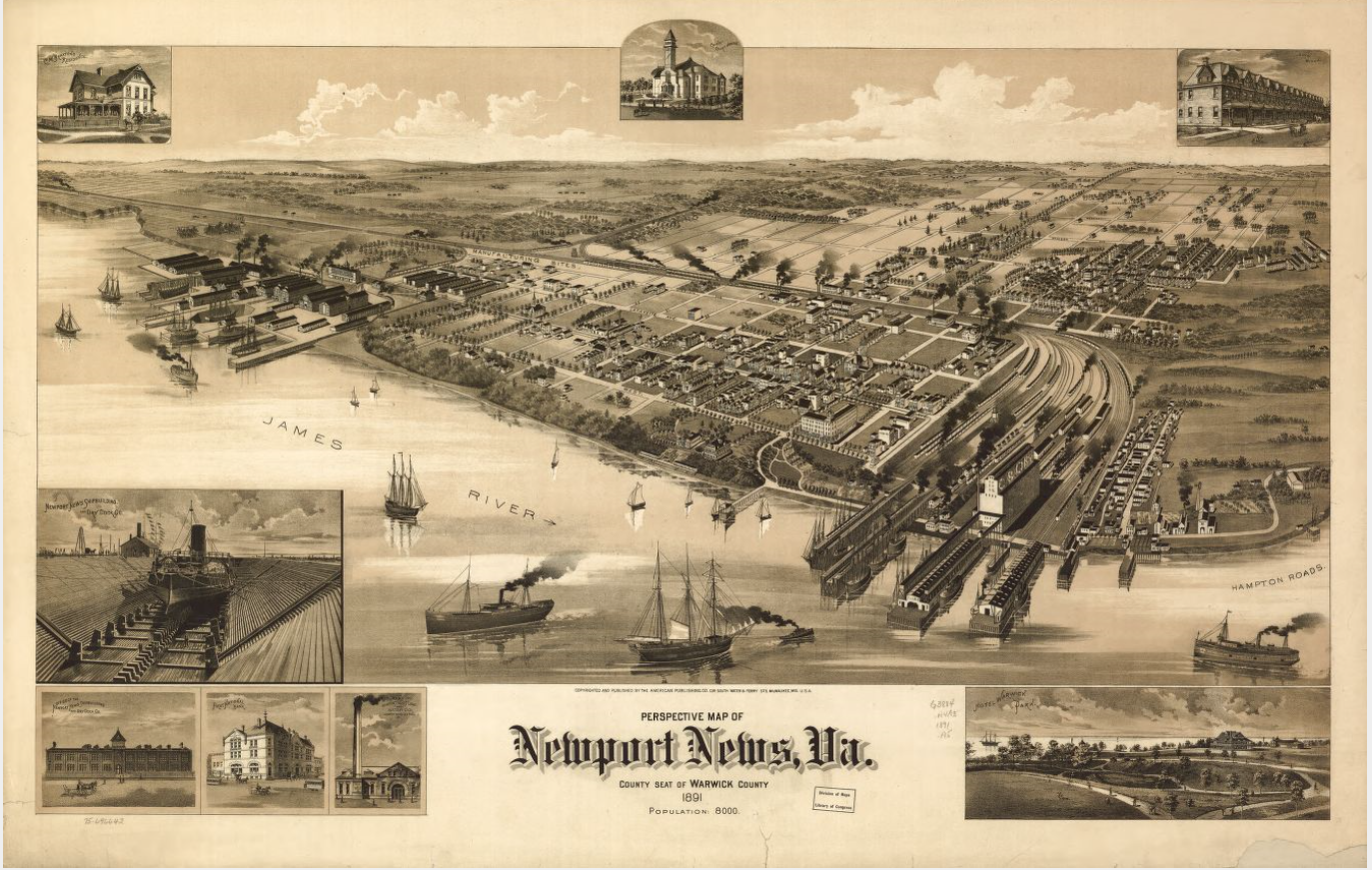

Newport News Facility

As announced in the Fall of 2019, ECR acquired its Newport News facility comprising 84 acres which includes two each 1,100 foot and 1,000 foot long piers with a water depth of 40 feet. The facility is ideally located at the foot of the Monitor Merrimac Bridge Tunnel and is poised for future investment and expansion. It has since then started improvement work on Pier 14, one of the facilities’ two piers. The progress along the 1,100 ft long pier is forging ahead with work underway comprising of new piles, new mooring system, power upgrades, as well as work on fire main, potable water, and compressed air. More facility improvement work will follow in other areas. The facility will allow ECR to transform its company profile as it looks to accommodate a broader diverse group of vessel owners and operators, such as Military Sealift Command, MARAD, Crowley, Maersk, and other commercial vessel operators.

Warwick Maritime Solutions

Warwick Maritime Solutions (WMS), a division of ECR, was established in 2019. Specializing in Government and Commercial ship repair and fabrication needs from small projects to large; we have the workforce and skillset to accommodate a full spectrum of projects. Whether on US Navy Ships, US Coast Guard vessels, transportation vessels, barges, tugboats, cruise ship owners, privately owned commercial vessels, or pleasure crafts, Warwick Maritime Solutions is ready to take on your project needs.

We believe in delivering the highest quality of workmanship on time, with competitive pricing and thorough attention to detail. WMS prioritizes the safety of our employees, customers, and the environment throughout the entire process. Our skilled and qualified workforce represents a broad spectrum of marine trades, including but not limited to welders, electricians, pipe fitters, and ship fitters.

Located within the River Port facility, WMS customers can take advantage of deep-water access with 1300 feet of bulkhead berthing (29’ depth at bulkhead) and two 1000-foot piers for pier-side repairs.

Fabrication Shop

ECR can provide your company with a wide range of fabrication and welding services. It does not matter what your needs are, we have the facilities, equipment, and staff to tackle projects big and small.

Services we offer include:

- Marine Pipe Fabrication

- Equipment Fabrication / Erection

- Module Fabrication

- Large Fabrications delivery via Truck and Barge

- Steel & Aluminum Plate Rolling, Bending, Cutting & Shaping

We are also an industry leader when it comes to custom fabrication services. ECR can manage and execute a wide array of projects that come in all shapes and sizes.

We can help with custom fabrication services including:

- Fabricate Stairways and Walkways per OSHA Standards

- Heavy and Light Fabrication

- Custom Fabrication

- Pipe Fabrication

- Inside Machine Shop

- HVAC Fabrication

Our shop is fully equipped with two 5-ton overhead cranes that extend through the length of our fabrication facility. We are also equipped with CNC Plasma Cutting Table, CNC Press Brake, CNC Pipe Bender, Plate and Angle Rollers, Lathes, Milling Machines, 20” Tilt Head Saw, and Welding Machines. We are constantly making new capital investments to keep us on the edge of technology as our ever-evolving business environment demands.